Portfolio

Hereinafter we present some of our realizations.

|

|

Supervisions | Human-Machine Interfaces |

|

|

SilView | Silos monitoring system |

|

|

PaletTre | Palletizer management |

|

|

SinLab | Data analysis archive |

|

|

SinScan | Film thickness monitoring |

|

|

SinMis | Energy consumption monitoring |

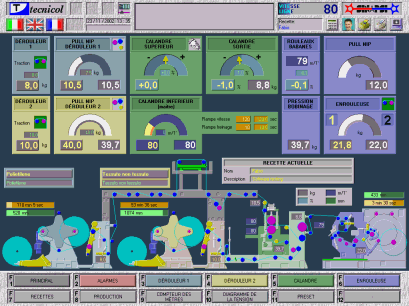

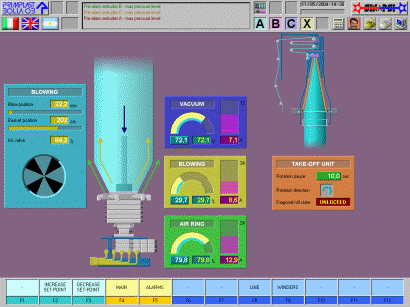

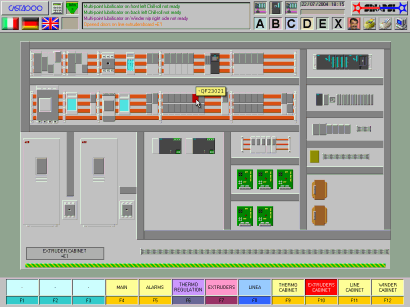

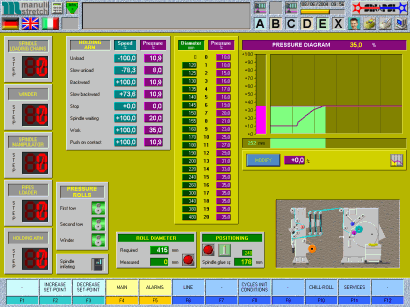

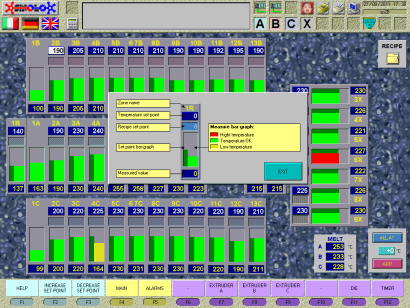

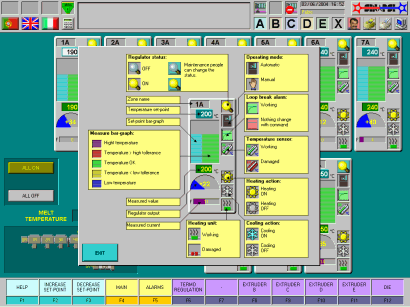

Supervisions

Interfaces development

The applications for the process management, simply called supervisions, are the leading product of the SINOLO's software development. With the definition supervisions are so indicated a multitude of works in the HMI field.

Following the customer's specifications we can use different SCADA packages and programming languages, although our preference is bound to Siemens' WinCC. In 13 years we developed 47 applications based on that platform, following every single step till the testing.

Software development

Since the pre-project commercial meetings, we follow all the development steps, proceeding hand in hand with the plant's construction, untill the testing to the final customer.

- Graphic design study, colors, symbologies

- Custom interfaces development

- Definition of the features and hierarchy organization of pages

- Synoptic panels creation from CAD drawings or photos

- Applications development

- Preliminary debugging and simulations

- Installations, commissioning, personnel training

- Technical assistance and future changes

Knowledge

In those years we gained experience in many different industrial fields:

- Flat die film extrusion line plants (CAST's)

- Blown film extrusion line plants

- Blown bioriented film extrusion line plants

- Adhesive spreaders machines

- Laminating machines

- Rewinding and unwinding machines

- Cutting machines and rewinding machines

- Water treatment and lifting plants

- Electromechanical components assembling machines

- Woodworking machines

- Steel industry plants

Maintenance options

Our supervisions can be equipped with different options. Below are shown the ones dedicated to the technicians.

- Advanced diagnosis with hardware alarms's visualization through power panel's synoptic panel.

Exportation and off-line consulting of the alarm reports.

- Preventative maintenance management with the option of inserting reminders about maintenance operations that, when reach the expiration period, are signalled.

Exportable reports of the performed maintenance works.

Management options

These components are designed to simplify the plant's economic management.

- Production report divided by batches, job orders or work shifts.

Exportable historic archive of the production.

- Machine downtime reports with the specification of the stopping cause and the downtime calculation.

Exportable historic archive of downtimes.

- Software for job orders insertion, production planning, work reports printing, orders condition and packing list.

These can be launched on the same supervision PC or from a remote station.

Technical operations

Some options to improve the plant integration with the factory.

- The expansion SinCCInet allows, through a remote web server, to consult pages that real-time question the plant.

It is possible to obtain management informations or process' parameters for technicians.

- All the described archives options can be integrated on the customer's server in form of database or in formats to agree upon.

|

|

SilView

Silos monitoring system

In the silos-equipped factories, personnel with different tasks (sales, inventory, production, etc.) have to know the content of that important part of the warehouse.

For this purpose SINOLO developed a client-server monitoring system. A PC interfaces to silos through level or weight transducers, monitoring the state in real-time.

The acquired informations are then send to remote stations that can elaborate statistics and reports.

Main features

The survey station provides the following services:

- Levels and weights measurement

- Hourly consumption view and remaining range

- Total amount by material

- Real-time display of the current state

- Reports prepation (on files or paper) asked on delay by clients

- Real-time display of the current state

- Hourly consumption view and remaining range

- Code and colour settings of the contained material (enabled clients only)

- Reports output (on files or paper)

- On delay reports planning (on files or paper) that will be send out by the server at the programmed time, even if the client is switched off

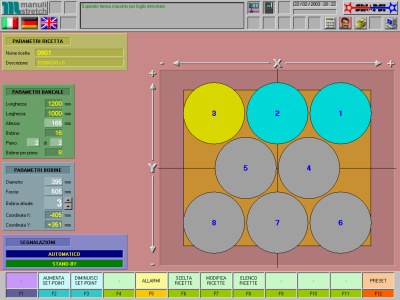

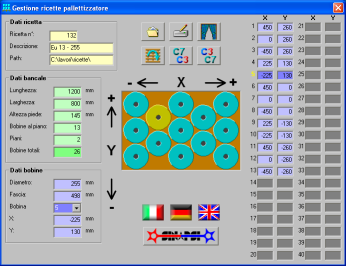

PalletTre

Palletizer management

Application for the supervision and the management of palletizers. Developed with WinCC, it can be used on a stand-alone workstation or it can be integrated on the plant's supervision.

It allows to monitor the different steps of the process, manages receipts, presets and diagnosis.

Main features

- Process' steps management.

- Receipts archive update by remote workstation.

- Can be integrated in the plant's supervision.

- Axes controls advanced diagnosis.

- User levels-protected settings.

- External editor for the remote changes at the receipts.

SinLab

Data analysis archive

This application realizes an historic archive of steel parameters, interfacing directly with an analyzer instrument. Data analysis of each production island, with time and prouction informations, are recorder on a central historic archive.

Is so obtained a batches-tracing system, useful for the production and the quality control.

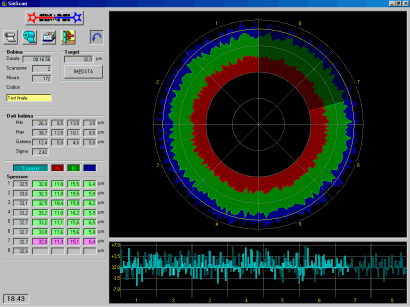

SinScan

Film thickness monitoring

Many plastic film production plants are equipped with a scanner for the instantaneous thickness measurement.

This software allows to generate historic archives for the measurements to obtain an immediate graphic representation of the production's quality.

Main features

- Polar graph of thickness (also different layers)

- Bargraph of the total thickness

- Minimum, maximum and average thickness indication for each scan

- Sigma and gamma calculation for each scan

- Archiving of production's parameter and quality indices for bobbin

- Report for bobbin

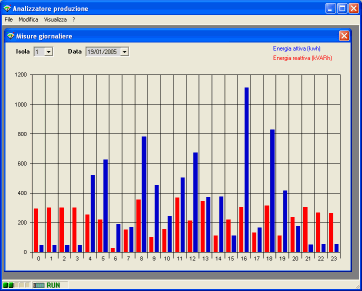

SinMis

Energy consumption monitoring

The energy cost it's always more an actual problem to deal with. So, it becomes important to optimize resources and, for that reason, is needed to know consumption datas greater.

For this purpose SINOLO developed the software called SinMis for energy consumption monitoring.

Using apposite energy measurement instruments, mounted on the device to monitor (plants or productive islands), the system obtain in real-time the energy consumption and other electrical measurements, then archived every time interval. On delay and from remote workstations it's possible to analize the consumption's trends in order to optimize the cost of the raw materials.

Main features

- Voltage and current of the 3-phases monitoring

- CosPhi and power line frequency monitoring

- Real and reactive power monitoring and recording

- Real and reactive energy monitoring and recording

- Hourly and daily consumption calculation and archiving

- Daily energy histogram

- Hourly power trend

- Datas exportation to office automation instruments